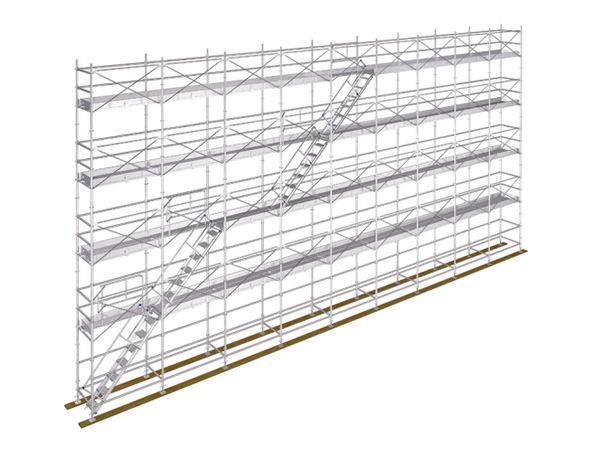

ALBA SYSTEM ®AUTHORIZED BY SCEA. JAPAN

What is "ALBA SYSTEM" ? …. It's the latest safe system of scaffold

The breakthrough, it had not be developed from conventional scaffold but it was born from quite new idea pursuing safety and work performance. In fact almost of traditional scaffold has been only designed for "how to make it stronger". On the other hand, ALBATROSS is designed for "how to make it safer" and "how to make it more efficient"

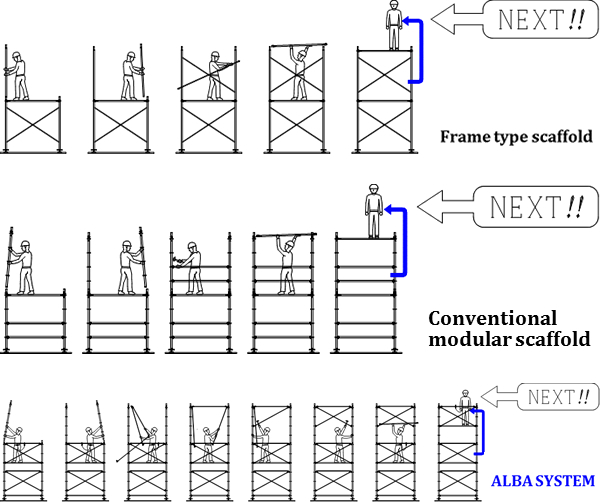

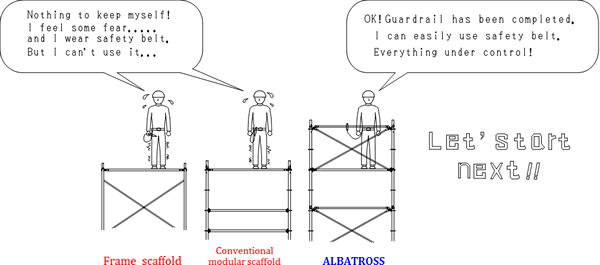

It possesses both advantage of frame type scaffold and modular scaffold. The strong points from frame type scaffold is quick, easy, and stability by cross braces. From modular scaffold, flexibility of assembling and less volume of the components. However most featured function of ALBATROSS is "Preceding Guardrail Method". Asked "why does person fall from scaffold?" The answer was that scaffolders have to assemble the components on the top platform of scaffold to erect it upper and upper. But there is nothing before he creates something out. In other word, always worker must operate at the altitudes without any guardrail.

The answer was very simple. "Attach next guardrail from lower tier".

In that way, when worker walks up to top platform, there has been completed the guardrails and he can grip them to keep himself.

Furthermore,the Preceding Guardrail possesses the function of cross brace as well.

That means that you can attach two components and two processes in one.

What is "Preceding guardrail method" ?

Under the conventional method of erection, scaffold is assembled tier by tier ( platform to platform , for example 1st. → 2nd. → 3rd. → 4th・・・).

In contrast, our new method takes a module of 0.5 ( 0.5th → 1.5th → 2.5th →3.5th・・・). "0.5" means a unit of guardrail with standards of half height of a tier. ( See below )

When the scaffolding is disassembled, scaffolders can work to detach the components on top platform where guardrails remain to the last.

The preceding guardrail is available to fastening safety belt. Unfortunately if a person falls , the guardrail deforms and absorbs the shock of fall momentum.

Easy handling with a hammer only.

Simple procedure under safe circumstance

Preceding Guardrails (right) and top rails and mid rails (left).

Preceding Guardrails (right) and top rails and mid rails (left).

(bay width 1219mm) Preceding Guardrails at both sides

Preceding Guardrails at both sides

( bay width 914mm )

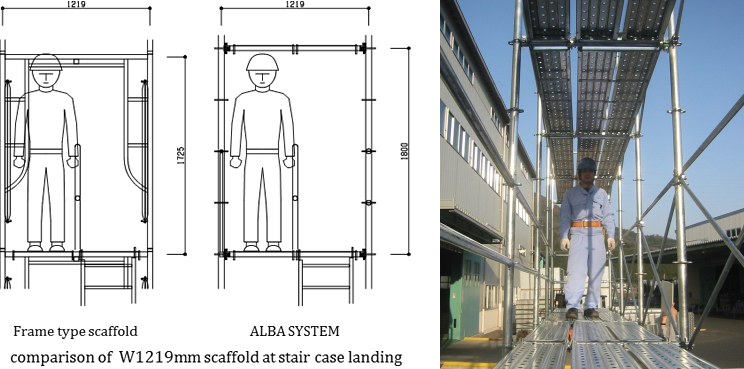

No internal reinforcers and best height of 1800mm for Asian people

No reinforcer in scaffold internal space. So you can get wide space as working area and comfortable access. Especially at stair case, it is very easy to go up down and returning.

A lift height of 1800mm makes you free from being tired even in long time working, without stress as well. You don't have to walk through to be bowing your head.

Light weight, but node possesses high tightening power and durable against frictional wear

Node and junction of ALBA SYSTEM

- Strong and Hi-Reliability

- The nodes of standard and ledger(transom) of ALBA SYSTEM are consisted of pressed plates and white heart malleable cast iron. That combination possesses high rigidity. The wedge penetrates standard's flange hole and special shaped "Snake Mouth" which is set at both end of ledger.

The node holds the ability against vibration and unexpected rising.

Ledger and transom is possible to attach for 4 directions of each standard flanges. You can flexibly assemble the scaffold fitting to complicated building form. Also can make wide working and storage platform.

- ABOUT US

- WHY JAPANESE SCAFFOLD?

- NEW SCAFFOLD FROM JAPAN

- MIGHTY BASE

- PRODUCTS(Catalog)